Antiscalant’s dynamic efficacy testing is an emerging testing which helps customers to understand the exact performance of their anti-scalant product and thereby take necessary actions to improve formulations if necessary.

Fortunately, at VIPANAN, due to our vast industrial experience, we have developed a specialization in performing Antiscalant’s efficacy testing. With a new perspective, introduced by VIPANAN, the Testing of antiscalants helps the manufacturer to define the working frame. With this perspective, two methods are very useful, which depend on test conditions, viz. Static & Dynamic.

Dynamic Efficacy Testing

- It is a close simulation of practical field operation performed with the help of synthetic water. The synthetic water can be designed considering the intra-relation of chemical complexes that affect the antiscalant efficiency. This technique is more complex because variables like temperature, pH, Calcium, Magnesium, sulfate, Silica, etc. are considered during this testing. This variation and deviation of parameters generate exhaustive data, which helps to conclude the antiscalant efficacy more precisely.

- Initially, designing synthetic water characteristics, with or without fillers, plays the most vital role in accomplishing the study of dynamic efficacy. Designing of synthetic water characteristics is mutually decided by VIPANAN and Customer, based on the significant data originated from static efficacy testing.

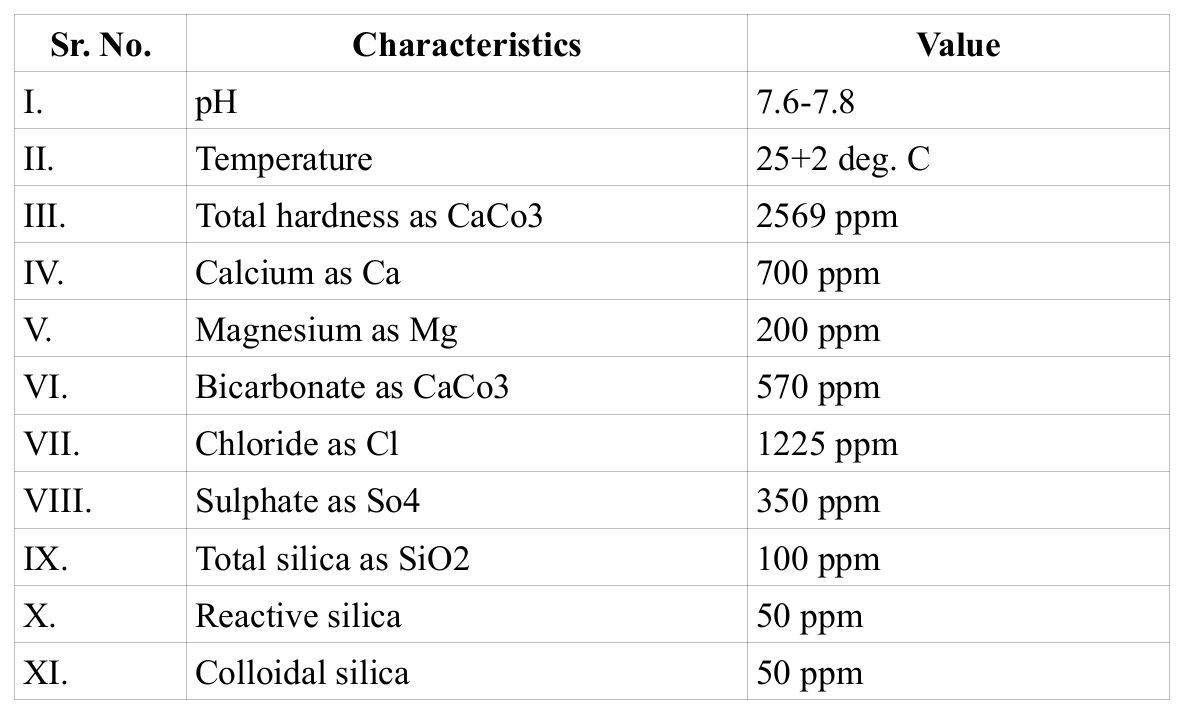

- These dynamic efficacy tests may involve extremely challenging water characteristics as described in the following test description. (indicative description only)

Aim of the Experiment

- To find out the efficacy of the threshold dosages of the given Antiscalant sample in dynamic conditions of operations in the Reverse Osmosis System.

Product Details Used for the Experiment

- Name of the Product/Anti-scalant Inhibitor- ABC

- Storage Condition – Room Temperature

Experimental Conditions

- A) Dosages of Scale Inhibitor Used – 2.5 ppm, 5 ppm

- B) Synthetic water –

- The synthetic water is prepared in DI water. The tentative characteristics of the synthetic water used are as follows (it may vary + 5 %) (indicative characteristics, these may vary from customer to customer)

Test Procedure

- The test is conducted for Blank (without dosing antiscalant), 2.5 ppm, and 5 ppm dosages of antiscalant. All the tests are run twice to avoid errors. For this, the circulation test of the synthetic water within the membrane in the absence of scale inhibitor (Blank) as well as in the presence of a particular dose of scale inhibitor is conducted for 100 hrs.

- The system details are monitored twice a day. Calcium, Magnesium, sulphate, and silica parameters have been analyzed as a foulant on the membrane post circulation of 100 hrs.

Fouling’s analysis results and observations are then summarized as shown below.

Observation:

- 01. Permeate flow of blank test (RO membrane system without scale inhibitor) has been decreased drastically within the first 25 hrs. of test running. Then it was lowly decreasing till 50 hrs of system run. After 50 hrs., permeate flow is observed to be decreasing gradually again. The overall reduction in permeate flow was approximately 74 %.

- 02. The overall reduction in permeate flow with 2.5 ppm of dosages was observed to be approximately 19.03 % while with 5 ppm of dosages was approximately 26.16 %.

- 03. Reject flow of blank system (RO membrane system without scale inhibitor) has decreased drastically within the first 25 hrs. After 50 hrs., the decrease in flow was gradual. The overall reduction in reject flow was approximately 66.20 %.

- 04. In case of 2.5 ppm dosages as well as with 5 ppm dosages, reject flow was observed to be increased by approximately 4-8 %.

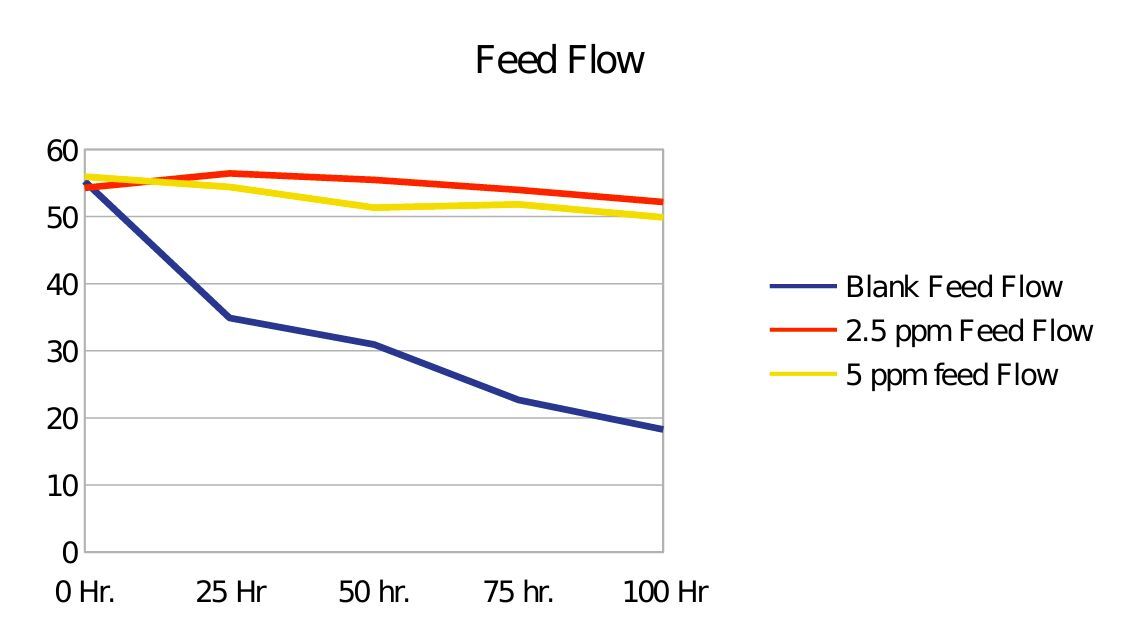

- 05. Feed flow of blank system ( RO membrane system without scale inhibitor) has been decreased drastically within the first 25 hrs. Then it was stable for 50 hrs. After 50 hrs. gradual decrease in the flow was observed. The overall reduction in feed flow was approximately 68.77 %.

- 06. The reduction in feed flow with 2.5 ppm of dosages was observed approximately 3.82 % while the reduction in feed flow with 5 ppm dosages was approximately 10.88 %.

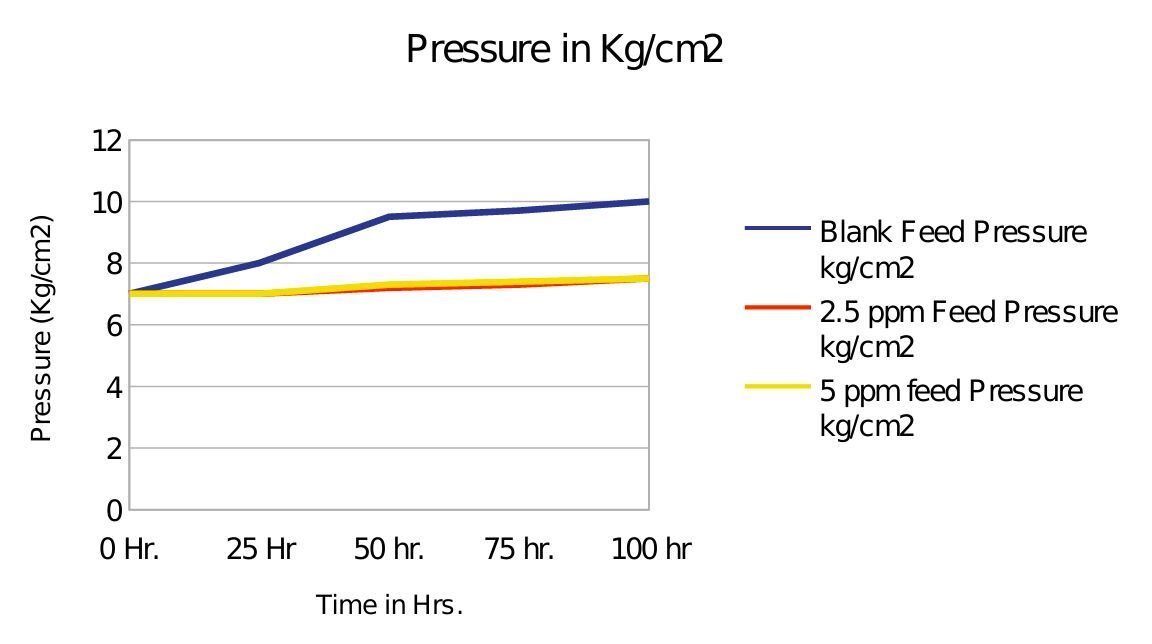

- 07. The feed pressure of the blank system has been increased by 42.86 % while in the case of 2.5 ppm dose and 5 ppm dose, feed pressure increased only up 7 %.

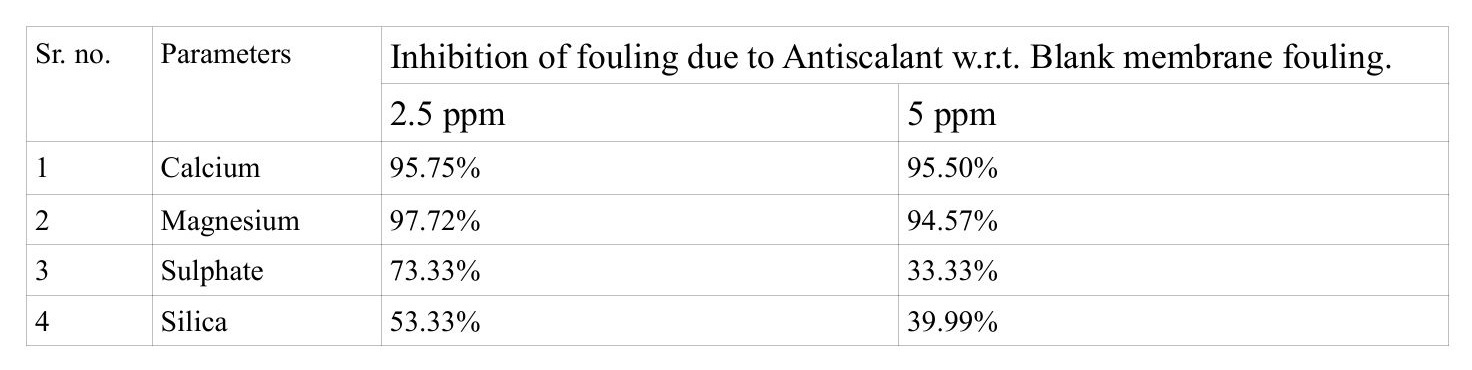

After the completion of the 100-hour run, the membranes of all the systems are deshelled and their fouling is analysed for the parameters such as Calcium, Magnesium, Sulphate, and Silica. The percentage inhibition of the Calcium, Magnesium, Sulfate, and Silica on the membrane processed with a 2.5 ppm dose and with 5 ppm dose of “ABC ” antiscalant is calculated with respect to blank membrane fouling, and the results are tabulated as follows.

- Remark

- 01. The scaling inhibition activity of the scale inhibitor “ABC “is very effective. The 2.5 ppm dose of scale inhibitor is more effective as compared to the 5 ppm dose in the Dynamic Efficacy testing of this particular scale inhibitor.

- 02. The inhibition of silica at 2.5 ppm may not be adequate, but significantly, it may control Magnesium Silicate and Calcium Silicate. Maximum inhibition of Calcium and Magnesium indicates that the product has given a good threshold value and inhibited Calcium and Magnesium Silicate, but it has not given adequate protection to polymerised silica.

- 03. It has been observed that a 5 ppm dose has given excellent inhibition for Calcium and Magnesium, and good inhibition for Sulphate and Silica. Still permeate flow has considerably dropped.

- 04. In case of 5 ppm dose, we cannot deny the possibility that it could affect the performance of the polyamide membrane.

- 05. Hence, it is necessary to assess the chemical compatibility study considering the membrane life of 3 years.

Using Dynamic Efficacy Testing for Antiscalant

- Choose System-Specific Antiscalants: Use dynamic test results to pick an antiscalant tailored to your feedwater composition.

- Monitor Recovery Rates: Since higher recovery increases scaling risk, adjust dosing strategies based on test outcomes.

- Combine with Membrane Autopsy: Use dynamic testing alongside membrane autopsy results for a complete picture of fouling and scaling risks.

- Don’t Rely on Generic Dosing Charts: Always validate dosing levels through dynamic testing rather than depending solely on standard guidelines.

- Regular Re-Evaluation: As feedwater chemistry changes seasonally or with source variation, retesting ensures continuous protection.

If we observed the above case, the manufacturer has clearly understood the performance of his antiscalants and the impact of excess dosage (5 ppm) on a system.