Vipanan is the 1st Third Party commercial laboratory in India who offers UF/MBR (Hollow Fiber) membrane autopsy services.

#membrane autopsy

With the experience of more than two decades in water analysis,Vipanan offers Membrane Autopsy Services to its customer's which helps to understand the exact root cause of membrane failure and define methods of troubleshooting.

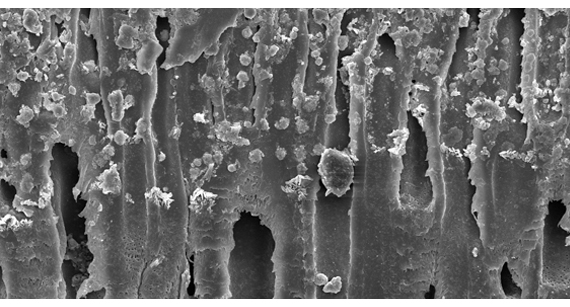

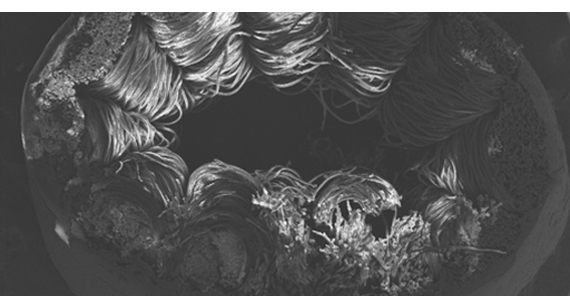

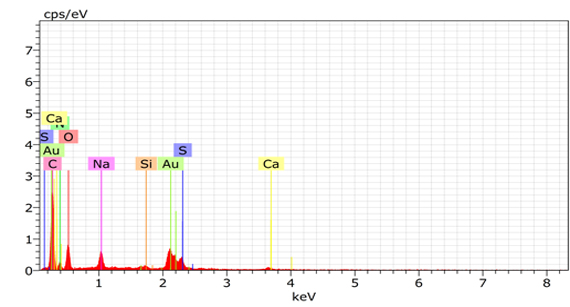

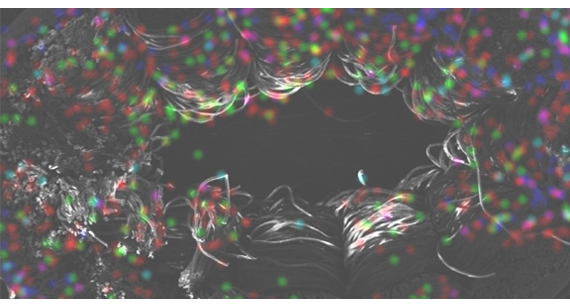

UF/ MBR membrane tend to undergo performance deterioration with time, which depends on the efficiency of the pre-treatment. The decline in performance due to fouling of the membrane, in many cases, can be restored to some extent by means of chemical cleaning. However, the performance decline due to irreversible damage to membrane polymer cannot be restored. In order to find out the actual reason for the irreversible decline in membrane performance, membrane autopsy becomes very essential, in addition to the investigation of the operational history of the membrane system.

All UF and MBR technologis are based on the ultrafiltration , but it can block or reduce the product flow due to organic , inorganic and microbiological deposition. In case of abnormal deposition of any organic or inorganic substance, standard CIP program is not effective. Our experience highlights that these membranes can be fouled by minerals and metals also. Also EPS (Extra Polymeric substances) provide base to organic and inorganic deposition.

When VIPANAN should be called for Autopsy??

When performance loss is observed through:

- Increased cleaning frequency

- Inefficient / Ineffective cleaning

- Flow restriction and frequent cleaning